Process GAP: Building from the Bottom Up

As business coaches we are often asked by companies to help assess the process breakdowns in operations (GAP assessment) and help them implement the improvement suggestions. This was the case with a client who has had problems manufacturing their product and delivering it to their customers on-time and within quality specifications.

I want to set the stage; our client was months behind delivering to their customers, creating a significantly negative cash-flow. This client was only able to deliver $1.2 million in product when Assured Strategy stepped in to help. The next month they delivered $1.6 million, the following month $2.1 million. three months into the process improvement project they increased their revenue 100% to deliver $2.4 million. All by filling in the GAP’s in their processes. There is still a great deal of work to do, but by all estimates they should be delivering $3 million plus every month moving forward. If you’d like improvements like this, we do this all the time at Assured Strategy.

When Assured Strategy was completing their GAP analysis, we learned our client was doing Lean Management training for their management and floor supervisors, which is putting the cart before the horse. The leaders did not have clarity of their own roles in the managing processes. No one really knew what their accountability or responsibilities were, and no one knew who had the real authority to make decisions.

If the management did not have clarity, it’s easy to see there wasn’t clarity around the policies and procedures. Equipment was outdated or not maintained, and materials were often incorrect or unavailable. The most telling issue was that none of these supervisors communicated these shortfalls to the executive team because they did not believe that anything would change.

Management overlooked the basic tenets for providing proper resources to their teams. They set them up to fail by expecting them to establish lean measures in their respective departments, with little to no support.

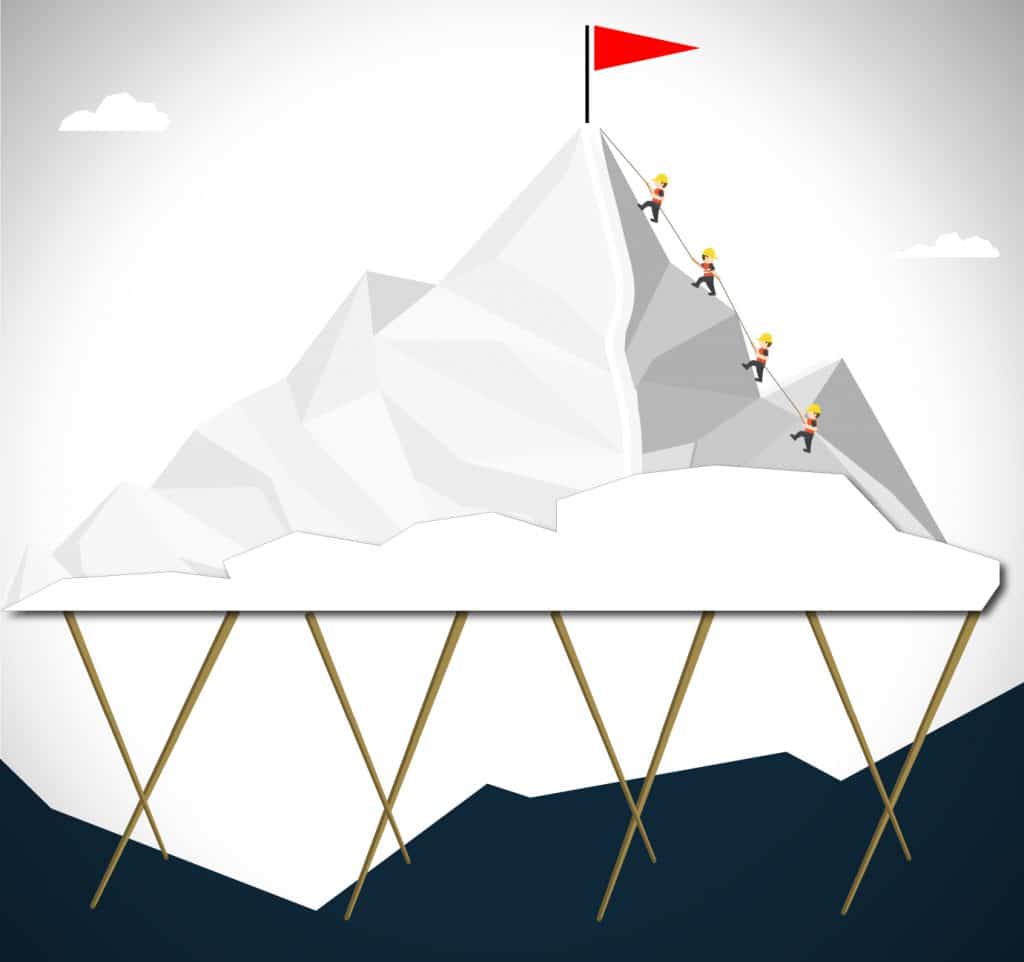

I wanted to paint a clear visual for this executive team, so I drew a crude picture showing the mountain that represents where they want to go. I then added the foothills and explained that they planned their climb at the top of the hills but did not start with the basics in staff leadership, so there is virtually no foundation to hold up their mountain vision.

One of the execs said, “It is like supporting the weight of all the work we have done with toothpicks”. This inspired me to write a blog because I’ve noticed a theme while working with various clients throughout the year. As a company suffers from growing pains, the execs seem to lose sight of the basics I’m talking from an operational standpoint; process-control is overshadowed by mid to high (business to corporate) level planning

The mistake is overlooking the need for change and improvements to the company’s under-structure (Functional Level). Growth requires change throughout; however, you must build or rebuild a strong and consistent foundation or the whole company structure could collapse.

The trend I am referring to is that management recognizes growth induced problems where the immediate action is implemented at the Business (Mid) Level. So, the question is, if no attention is paid to the fundamental level, what is supporting those changes?

When I am wearing my consulting hat, I guide these exec teams to redirect their efforts into building support at the lowest point. It is amazing to witness these teams embark on their journey of discovery learning what is really going on deep within the foundation of their company. They are surprised by the perspective of the fundamental level employees. They begin to work with line-staff to build trust which is usually lacking. It does not happen overnight, but with concentrated effort, communication becomes the power behind accomplishment.